TIG Welding and How the GTAW Process Works

When precision, strength, and clean weld aesthetics matter, few welding processes compare to TIG welding, also known as GTAW (Gas Tungsten Arc Welding). At Fabrication Pros here in Calgary, Alberta, TIG welding is one of the core services we provide for residential, commercial, and industrial clients. From aluminum repairs to stainless steel fabrication, TIG welding delivers unmatched quality — and our certified welders use it daily on projects requiring the highest level of craftsmanship.

In this guide, we’ll break down the benefits of TIG welding and explain the GTAW process step-by-step, so you understand exactly why this method is trusted across Alberta’s industries.

What Is TIG Welding (GTAW)?

TIG welding, or Gas Tungsten Arc Welding, is a process that uses a non-consumable tungsten electrode to create an arc that melts the base metal. Instead of the electrode melting (like in MIG or stick welding), the welder controls the weld puddle and adds filler metal manually when needed.

A shielding gas — most commonly argon — protects the weld area from contamination and oxidation.

Because of this high level of control, TIG welding produces the cleanest, strongest, and most precise welds in the industry.

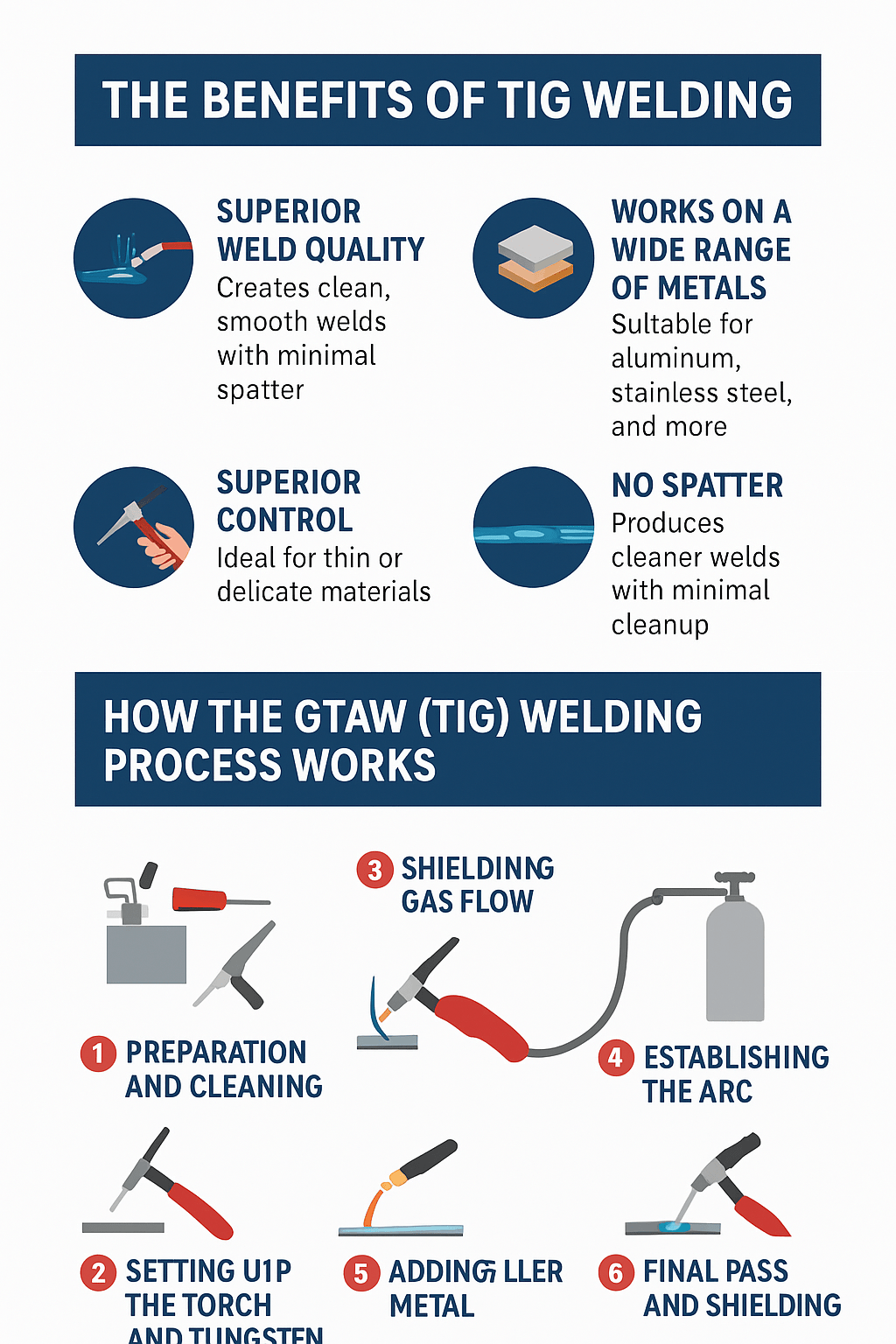

The Benefits of TIG Welding for Calgary Welding Shop Projects

1. Superior Weld Quality

TIG welding creates:

- Clean, smooth bead appearance

- Minimal spatter

- Strong, durable welds

- High aesthetic appeal

This makes TIG the preferred choice for aluminum tanks, stainless steel components, ornamental metalwork, and precision fabrication.

2. Works on a Wide Range of Metals

TIG welding is extremely versatile. It can be used on:

- Aluminum

- Stainless steel

- Mild steel

- Copper

- Titanium

- Chrome alloys

- Exotic metals

This flexibility allows our Calgary welding shop to take on everything from industrial repairs to automotive parts, brewery equipment, and custom fabrication.

3. Superior Control for Thin or Delicate Material

Unlike MIG or Stick welding, which can easily burn through thin metal, TIG is ideal for precision applications. Our welders can create strong welds on thin aluminum, stainless steel tubing, or lightweight components without distortion.

4. No Spatter and Minimal Cleanup

Because filler metal is added manually and the electrode doesn’t melt, TIG welding produces:

- Zero slag

- Zero spatter

- Minimal cleanup

- Cleaner finishes for painted or polished surfaces

In decorative or food-grade applications, this is a major advantage.

5. Stronger, More Reliable Welds

TIG welding is known for producing:

- Deep penetration

- Strong fusion

- Consistent structural integrity

This is why industries like aerospace, oil and gas, agriculture, transportation, manufacturing, and construction rely heavily on the TIG process.

How the GTAW (TIG) Welding Process Works: Step-by-Step

Below is the simplified breakdown of how our certified Calgary welders perform TIG welding in our shop and on mobile service calls:

1. Preparation and Cleaning

TIG welding requires extremely clean material. We prep the metal by:

- Removing paint, coatings, or oxidation

- Cleaning with acetone

- Brushing aluminum with a stainless wire brush

- Ensuring tight fit-ups

Clean metal = clean welds.

2. Setting Up the Torch and Tungsten

We choose the correct tungsten type based on the metal:

- Red (Thoriated) – for steel and stainless

- Green (Pure) or Blue/Gold (Lanthanated) – for aluminum

The tungsten is sharpened to a fine point for precision arc control.

3. Shielding Gas Flow

Pure argon gas is used to shield the weld area.

This prevents:

- Porosity

- Contamination

- Oxidation

For aluminum, argon provides smooth, stable arc performance.

4. Establishing the Arc

The welder uses a foot pedal or finger control to:

- Start the arc

- Control amperage

- Maintain a stable puddle

This precise control is one of the biggest strengths of GTAW.

5. Adding Filler Metal

If additional metal is needed, filler rod is dipped into the puddle by hand. This allows:

- Exact control over bead profile

- Smooth transitions

- Stronger welds

Common filler rods include ER4043, ER5356, ER70S-2, and stainless grades depending on the application.

6. Final Pass and Shielding

After the weld is complete, the torch continues shielding the weld until it cools slightly.

This prevents:

- Weld discoloration

- Shielding gas turbulence

- Structural weaknesses

Proper post-flow is essential for strong TIG welds.

Why Calgary Chooses Us for TIG Welding

At Fabrication Pros, we offer:

- Certified TIG welders with years of experience

- High-precision aluminum and stainless repairs

- Mobile welding service across Calgary and surrounding areas

- Custom fabrication for residential, commercial, and industrial clients

- Fast turnaround and guaranteed quality

We handle everything from aluminum diesel tanks and stainless handrails to machine components, industrial piping, and custom metalwork.

Need Expert TIG Welding in Calgary, Alberta?

Our team provides professional TIG/GTAW welding services in-shop or on-site. If you need clean, precise, and reliable welds, we’re the welding company Calgary businesses trust.

📞 Call us at 587-805-0560

📍 Serving Calgary, Airdrie, Okotoks, Cochrane & surrounding Alberta

🌐 Contact Us for a free quote