A Complete Guide to GTAW TIG Welding

When it comes to achieving clean, precise, and high-quality welds, GTAW welding—also known as TIG welding—stands at the top of the welding industry. For Calgary businesses that demand exceptional craftsmanship, from stainless steel fabrication to aluminum welding repairs, TIG welding is often the preferred solution. Whether you’re a facility manager, contractor, or industrial shop owner, understanding the benefits and process of TIG welding can help you choose the right welding service for your project.

This guide breaks down what GTAW/TIG welding is, how it works, best practices, filler wire types, and where it is most commonly used across Calgary’s residential, commercial, and industrial sectors.

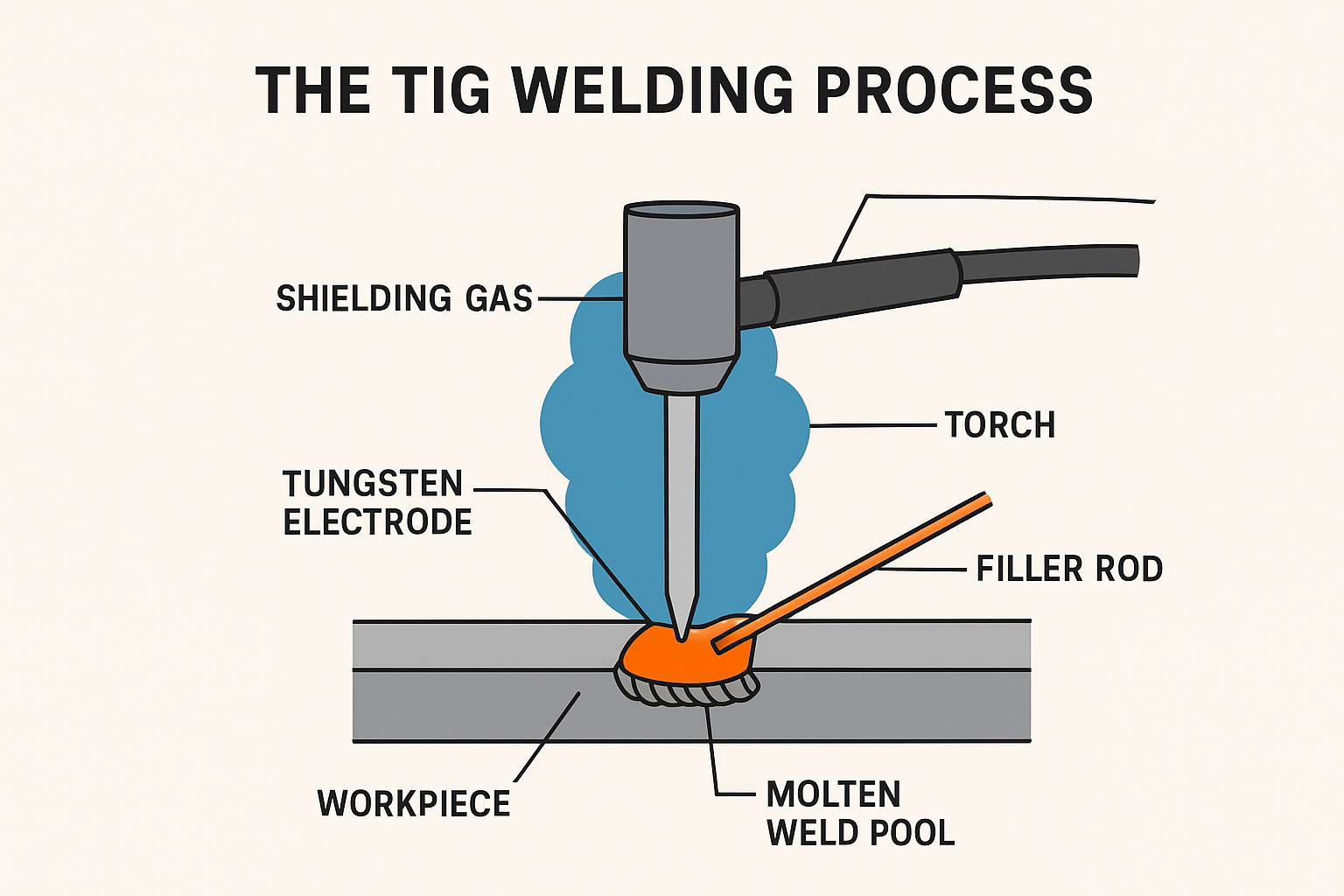

What Is GTAW (TIG) Welding?

GTAW stands for Gas Tungsten Arc Welding, often referred to as TIG welding—Tungsten Inert Gas.

Unlike other welding processes, TIG welding uses a non-consumable tungsten electrode to create the arc. The weld puddle is protected by an inert shielding gas, most commonly argon, to prevent contamination. A separate filler rod is added manually when needed, offering unmatched precision and control.

This welding method is widely used in Calgary for high-end fabrication, aerospace components, pressure piping, food-grade stainless equipment, and thin-gauge aluminum projects where appearance and structural integrity are critical.

Why TIG Welding Is Preferred in Calgary: Key Advantages

✔ 1. Superior Weld Quality and Appearance

TIG welding produces incredibly clean welds with no spatter, minimal smoke, and excellent bead appearance. This is ideal for visible structural elements such as railings, decorative metalwork, custom fabrication, and stainless steel assemblies.

✔ 2. Works on a Wide Range of Metals

TIG welding excels on:

- Aluminum

- Stainless steel

- Mild steel

- Titanium

- Chromoly

- Copper alloys

- Nickel-based alloys

This versatility makes it valuable for industrial repair work across Calgary’s oil, gas, and energy sectors.

✔ 3. Ultimate Precision and Heat Control

Because the filler rod is added manually, the welder has full control of the:

- Heat input

- Weld puddle size

- Bead shape

- Penetration

This precision reduces distortion—especially important for thin materials, sheet metal, and aesthetic welds.

✔ 4. Strong, High-Integrity Welds

TIG welding creates a very strong, contamination-free weld, ideal for pressure-bearing or load-bearing structures.

How the GTAW (TIG) Welding Process Works

Below is a simplified but comprehensive breakdown of the TIG process used by professional welders in Calgary:

1. Material Preparation

TIG welding requires extremely clean surfaces. The welder prepares the metal by:

- Removing oil, paint, rust, coatings

- Cleaning with a stainless steel brush for aluminum

- Wiping with acetone or alcohol

- Ensuring tight, well-fitted joints

Proper preparation ensures stronger bonding and a cleaner weld bead.

2. Setting Up the Torch and Tungsten

The welder chooses the correct tungsten electrode type and diameter, such as:

- 2% Thoriated (Red) – common for DC mild steel and stainless

- 2% Lanthanated (Blue/Gold) – versatile for AC and DC

- Pure Tungsten (Green) – older standard for AC aluminum

The electrode is sharpened to a precise point to control the arc shape.

3. Shielding Gas Flow (Usually Argon)

Pure argon (99.99%) is used in most Calgary fabrication applications because it:

- Provides arc stability

- Keeps the weld puddle clean

- Prevents contamination

Flow rates generally range from 10–20 CFH, depending on cup size and welding conditions.

4. Establishing the Arc

The welder uses a foot pedal or fingertip control to ignite and regulate the arc. The tungsten does not touch the metal. This creates a focused heat zone for precision work.

5. Adding the Filler Material

When required, the welder dips a filler rod into the molten puddle, controlling:

- Penetration

- Strength

- Weld bead shape

This allows for extremely clean, stacked-dime welds.

6. Final Pass and Shielding Coverage

Once the welder finishes the joint, the torch remains in place briefly to maintain gas shielding as the weld cools. This prevents:

- Pitting

- Oxidation

- Color changes in stainless steel

Best Practices for High-Quality TIG Welding

Professional TIG welders follow several strict techniques to ensure top results:

🔧 Maintain Proper Tungsten Geometry

A sharp, uniform tungsten shape leads to:

- Better arc stability

- Cleaner puddle control

- More consistent welds

🔧 Keep the Filler Rod Inside the Gas Shield

To avoid contamination, the filler metal must stay inside the gas coverage.

🔧 Control Heat Input

Too much heat causes distortion or burn-through, especially in thin aluminum or stainless.

🔧 Use the Correct Tungsten Type

Each metal requires a specific tungsten for optimal arc stability.

🔧 Maintain Cleanliness

Contaminants instantly ruin TIG weld quality — cleanliness is crucial.

Common TIG Welding Filler Rod Types (GTAW Wire Types)

TIG welding uses bare filler rods, not spooled wire. Common types include:

For Mild Steel

- ER70S-2 – Excellent for root passes and clean welds

- ER70S-6 – Higher deoxidizers for welding over mill scale

For Stainless Steel

- ER308L – For 304/304L stainless

- ER309L – For dissimilar metals

- ER316L – For 316/316L or corrosion-resistant applications

For Aluminum

- ER4043 – Smooth, clean welds with lower cracking risk

- ER5356 – Stronger, great for structural aluminum

For Exotic Metals

- ER70S-2 Chromoly – For race car frames

- CP Titanium Rods – Aerospace and corrosive environments

- Nickel Alloy Rods (Inconel fillers) – High-heat, high-stress parts

Each filler metal is chosen based on strength, corrosion resistance, ductility, and compatibility with the base material.

Common Applications of GTAW (TIG) Welding in Calgary

TIG welding is essential across multiple Calgary industries:

1. Aluminum Welding & Fabrication

Used for:

- Truck beds

- Aluminum ramps

- Fuel tank repairs

- Trailers

- Guards and handrails

2. Stainless Steel Fabrication

Ideal for:

- Food processing equipment

- Commercial kitchens

- Stainless railings

- Brewery lines

- Medical environments

3. Industrial Repairs

Oil & gas, manufacturing, and mechanical shops rely on TIG welding for:

- Piping systems

- Tanks

- Structural components

- Pressure-rated welds

4. Custom Metal Fabrication

TIG is preferred when weld appearance matters:

- Custom gates

- Decorative metalwork

- Artistic steel and aluminum pieces

5. Automotive & Motorsports

Used for:

- Exhaust systems

- Turbo piping

- Chromoly roll cages

- Thin-wall aluminum components

6. Aerospace Components

Calgary’s growing aerospace and engineering sectors rely on TIG welding for:

- Precision assemblies

- Light alloys

- High-performance metals

Why Calgary Businesses Choose TIG Welding Services

Calgary companies demand durability, precision, and reliability. TIG welding provides:

- Aesthetically perfect welds

- Strong, contamination-free joints

- Superior performance on stainless and aluminum

- Precision welding for complex or sensitive parts

Whether for on-site repairs, mobile welding, or shop-based fabrication, TIG is often the best welding solution for high-quality metalwork.

Looking for Professional TIG Welding Services in Calgary?

If your project requires:

- High-precision welds

- Stainless steel or aluminum fabrication

- Clean, spatter-free welding

- Industrial-grade repairs

- Custom metal components

A professional TIG welder can deliver results that stand above other welding processes. TIG welding is the gold standard for durability, accuracy, and appearance—and the best choice for Calgary’s demanding industries.

[…] TIG Welding and How the GTAW Process Works […]