What Is SMAW Welding? A Complete Guide to Stick Welding

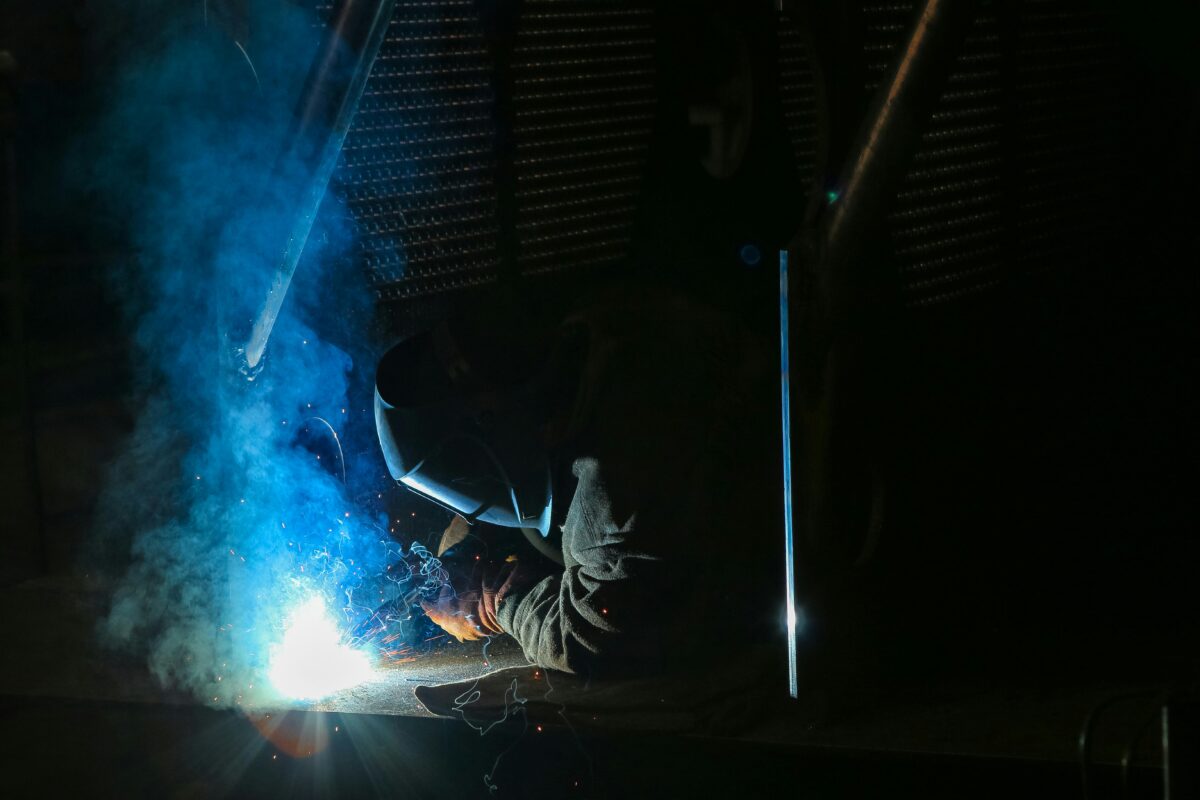

SMAW welding, short for Shielded Metal Arc Welding, is one of the most common and dependable welding processes used in the industry today. Often referred to as stick welding, SMAW is known for its versatility, strength, and reliability — making it ideal for structural steel, repair work, and outdoor projects.

How SMAW Welding Works

In SMAW welding, an electrode coated in flux is used to carry the electric current that creates an arc between the electrode and the base metal. This arc generates intense heat, which melts both the electrode and the workpiece to form a solid weld joint.

As the electrode melts, the flux coating releases shielding gases and forms a layer of slag over the weld. This protective layer prevents contamination from oxygen and moisture, ensuring a strong, clean weld once the slag is removed.

Because SMAW does not rely on external shielding gas, it performs exceptionally well in outdoor or windy conditions where other welding methods might struggle.

Advantages of SMAW Welding

SMAW remains one of the most popular welding techniques worldwide due to its durability and flexibility. Some of its top advantages include:

- ✅ Versatile Applications: Works on a wide range of metals, including steel, stainless steel, cast iron, and alloy steel.

- ✅ Portable and Flexible: Requires minimal equipment, making it ideal for on-site and field welding.

- ✅ Strong, Reliable Welds: Produces deep weld penetration for long-lasting strength.

- ✅ Cost-Effective: Simple equipment setup keeps costs low for both industrial and repair projects.

- ✅ Excellent for Outdoor Use: Performs well in variable weather conditions, unlike MIG or TIG welding.

Common Uses for SMAW Welding

Because of its toughness and adaptability, SMAW is used across many industries and applications, including:

- Construction and structural steel fabrication

- Pipeline and pressure vessel welding

- Agricultural and heavy equipment repair

- Shipbuilding and offshore structures

- Industrial maintenance and field services

SMAW vs. Other Welding Methods

Compared to GMAW (MIG welding) and GTAW (TIG welding), SMAW is more portable and better suited for heavy-duty work in challenging environments. While MIG and TIG produce cleaner and more precise welds, SMAW excels in strength, simplicity, and versatility — especially for repairs, construction, and outdoor applications.

Professional SMAW Welding Services

At Fabrication Pros, we provide professional SMAW welding services in Calgary for industrial, commercial, and structural projects. Our experienced welders deliver durable, high-quality welds that meet exact safety and performance standards — whether you need on-site repairs or new fabrication work.