When it comes to welding, whether you’re working on aluminum fuel tanks, structural steel, or heavy equipment — understanding welding polarity is essential for strong, clean, and efficient welds. At Fabrication Pros we get asked: What’s the difference between straight and reverse polarity — and which one should I use?

In this post, we’ll break down the science behind welding polarity and explain how it affects penetration, bead profile, and weld quality.

🔧 What Is Welding Polarity?

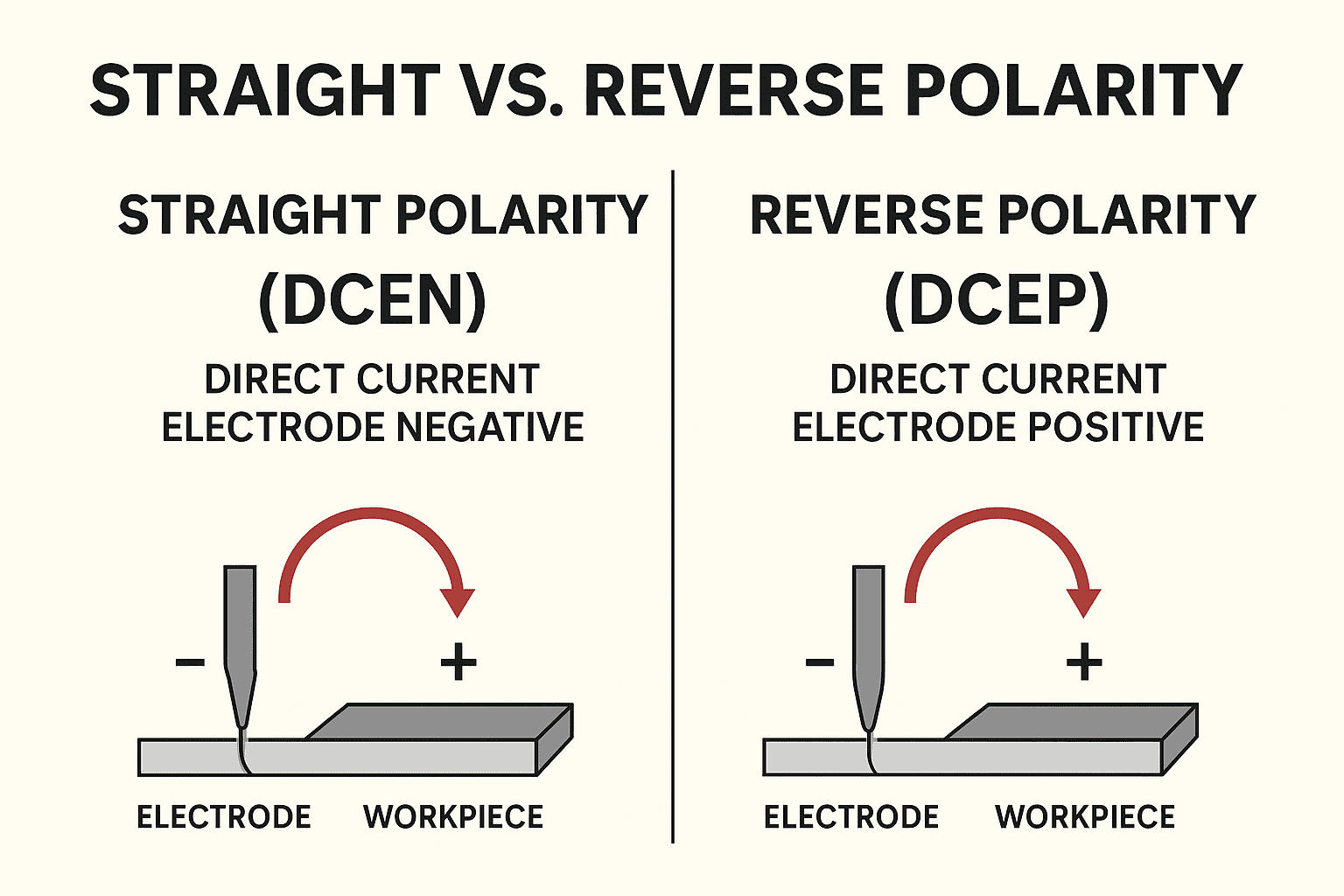

Welding polarity refers to the direction of current flow in a welding circuit. In any DC (direct current) welding setup, electricity flows from the negative terminal to the positive terminal. By switching which side the electrode connects to, welders can change how heat is distributed between the electrode and the workpiece.

There are two main types of polarity used in DC welding:

- Straight Polarity (DCEN) – Direct Current Electrode Negative

- Reverse Polarity (DCEP) – Direct Current Electrode Positive

Straight Polarity (DCEN) – Deep Penetration for Heavy Welding

In straight polarity, the electrode is negative and the workpiece is positive. About two-thirds of the heat is concentrated on the workpiece, providing deeper penetration and faster material fusion.

✅ Best For:

- TIG (GTAW) welding aluminum or stainless steel

- Thicker materials

- Pipe welding and structural applications

⚡ Key Benefits:

- Deep weld penetration

- Faster travel speeds

- Less electrode consumption

⚠️ Things to Watch:

- Can produce a narrower bead

- Not ideal for thin materials (risk of burn-through)

🔄 Reverse Polarity (DCEP) – Cleaner Welds and Better Fusion

In reverse polarity, the electrode is positive, and the workpiece is negative. This reverses the heat distribution — now, most of the heat is concentrated on the electrode tip. The result is shallower penetration but better surface cleaning due to the electron flow that removes surface oxides.

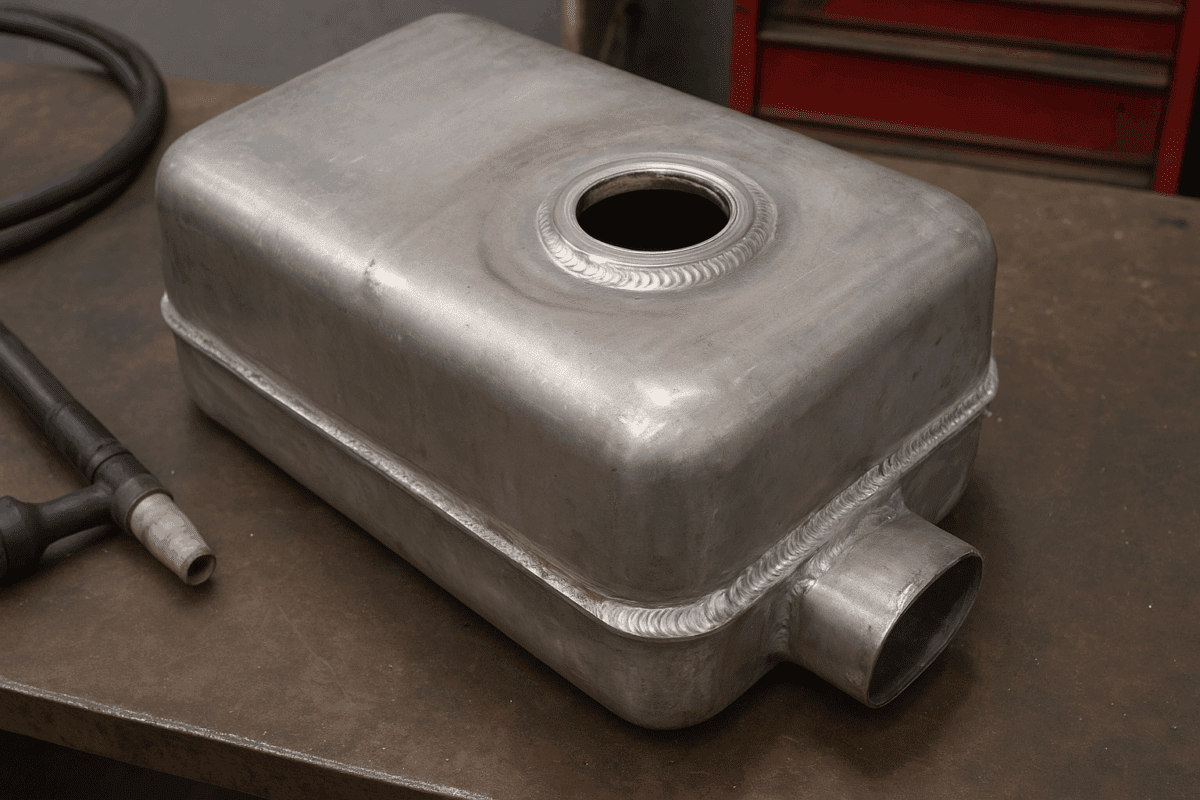

✅ Best For:

- MIG (GMAW) welding aluminum and mild steel

- Welding thin sheet metal

- Welds that require clean, smooth beads

⚡ Key Benefits:

- Excellent cleaning action

- Reduced spatter

- Smooth, consistent weld appearance

⚠️ Things to Watch:

- Lower penetration depth

- Slightly slower welding speed

🧰 Choosing the Right Polarity for the Job

The right polarity depends on the material type, thickness, and welding process:

| Welding Process | Recommended Polarity | Typical Use |

|---|---|---|

| TIG (GTAW) | Straight Polarity (DCEN) | Aluminum, stainless, precision work |

| MIG (GMAW) | Reverse Polarity (DCEP) | General fabrication, automotive, sheet metal |

| Stick (SMAW) | Depends on Electrode Type | Varies by rod type (E6010 uses DCEP, E6013 can use both) |

If you’re unsure which polarity to use, consult your electrode manufacturer’s datasheet or reach out to an experienced welding technician — using the wrong polarity can cause weak welds, excess spatter, or porosity.

🏗️ Calgary’s Trusted Welding Professionals

At Fabrication Pros we specialize in mobile and in-shop welding services throughout Calgary and Southern Alberta. From heavy equipment repairs and bucket hard facing to aluminum fuel tank welding, our certified rig welders ensure every weld meets the highest safety and performance standards.

Whether you need expert advice on welding polarity or on-site repairs, our team is here to help.

📞 Get in Touch

Looking for a professional Calgary welding company?

Contact Fabrication Pros today for reliable, certified, and locally trusted welding solutions.