MIG welding—also known as Gas Metal Arc Welding (GMAW)—is one of the most widely used welding processes in both industrial and commercial environments. Known for its speed, versatility, efficiency, and consistent weld quality, MIG welding is a go-to method for fabrication projects, automotive repair, construction, equipment repair, and general manufacturing.

In this in-depth guide, we break down how MIG welding works, the equipment involved, wire types, best practices, and the industries that rely on MIG welding every day. Whether you’re a beginner, a professional welder, or a business owner researching welding services, this article covers everything you need to know.

What Is MIG Welding?

MIG (Metal Inert Gas) welding is a welding process where a spool-fed wire electrode is continuously fed through a welding gun, where it melts and fuses the metal surfaces together. Unlike stick welding, which uses a consumable electrode rod, MIG welding uses a wire and shielding gas to protect the weld from contamination.

This results in:

- Clean, smooth welds

- Faster travel speeds

- Less spatter

- Minimal welding fumes

- Easier learning curve for beginners

Because of its efficiency and adaptability, MIG welding is one of the most commonly used welding methods worldwide.

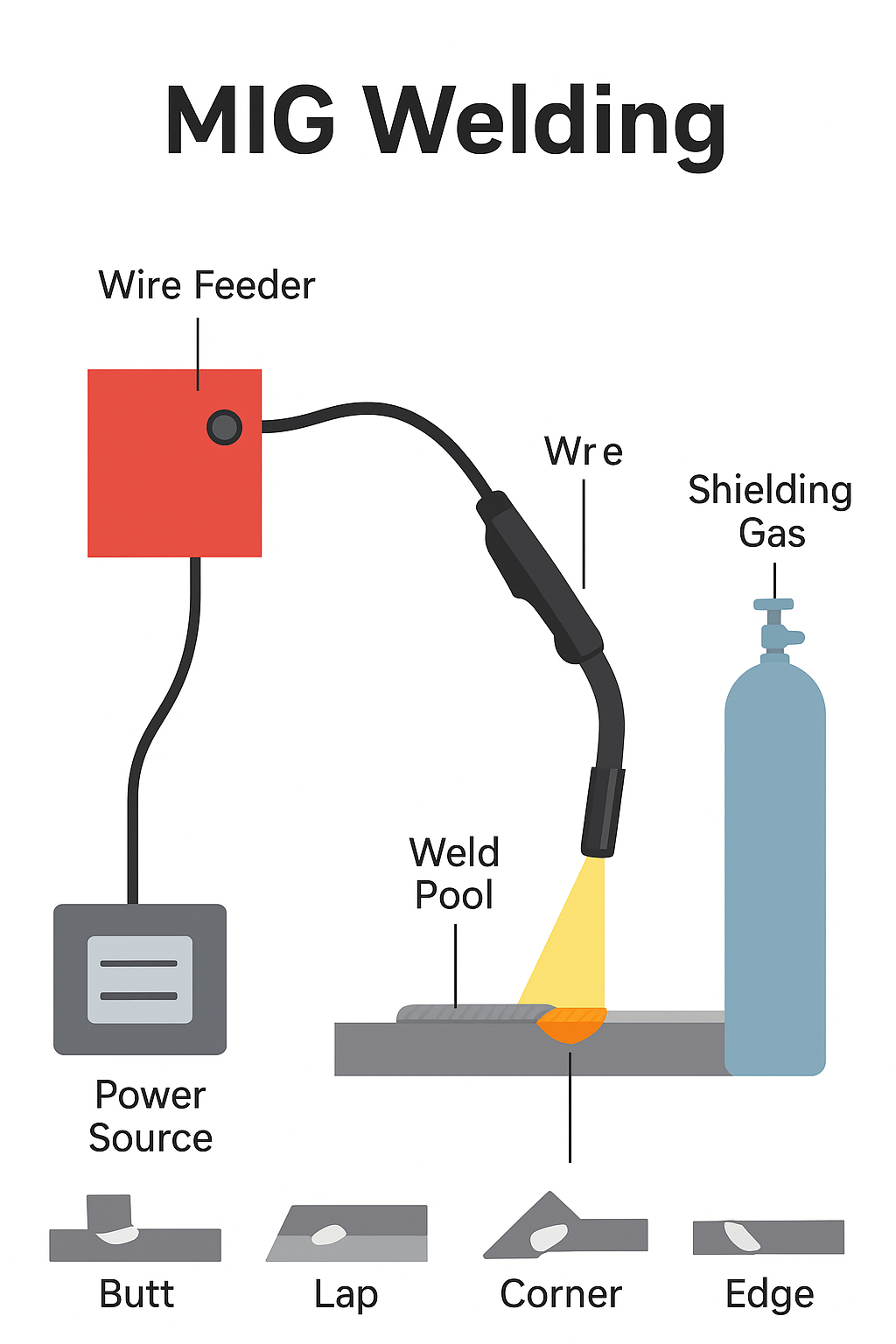

How MIG Welding Works

The MIG process relies on four main components working together:

1. Power Source

The machine provides a constant voltage, usually DC+, which stabilizes the arc and ensures consistent deposition.

2. Wire Feeder

A motorized wire feeder pushes welding wire through the MIG gun at a controlled, adjustable speed.

The wire acts as:

- Filler material

- Electrode

3. MIG Gun

The MIG gun delivers:

- The wire electrode

- Electrical current

- Shielding gas

A trigger controls the wire feed and arc initiation.

4. Shielding Gas

A blend of gases protects the weld pool from atmospheric contamination.

Common gases include:

- C25 (75% Argon, 25% CO₂) – Most common for mild steel

- 100% CO₂ – Deep penetration, more spatter

- 100% Argon – Aluminum and non-ferrous metals

- Argon/Helium Mixes – Stainless steel and specialty metals

The shielding gas is crucial—without it, the weld suffers from porosity, poor fusion, and contamination.

Advantages: MIG Welding

MIG welding offers several benefits, making it popular across industries:

✔ Fast welding speeds

Perfect for production and fabrication shops.

✔ Easy for beginners to learn

MIG is more forgiving and easier to control than TIG or stick welding.

✔ Versatile across many metals

MIG works on:

- Mild steel

- Stainless steel

- Aluminum

- Nickel alloys

- Some copper alloys

✔ Clean weld appearance

Minimal cleanup is needed due to reduced spatter.

✔ Excellent for both thin and thick materials

Adjustable heat control makes MIG suitable for materials from 24 gauge sheet metal to heavy structural steel.

Common MIG Welding Wire Types

Choosing the right wire is essential for a strong, clean weld. The most common wires include:

1. ER70S-6 (Mild Steel Wire)

- The most popular MIG welding wire

- Great for rusty or dirty steel

- Produces a strong, ductile weld

- Works well with C25 gas

Ideal for fabrication, construction, automotive, pipelines, and general repairs.

2. ER308L / ER309L (Stainless Steel Wire)

Used for:

- Stainless railings

- Food-grade equipment

- Chemical processing components

Provides excellent corrosion resistance.

3. ER4043 & ER5356 (Aluminum MIG Wire)

ER4043: Smooth bead appearance, great for cast aluminum

ER5356: Higher strength, used for marine and structural aluminum

Requires:

- 100% Argon

- Spool gun or push-pull system

4. Flux-Core MIG Wire (FCAW)

No shielding gas required, making it ideal for:

- Outdoor work

- Windy conditions

- Heavy structural welding

Produces deeper penetration but more spatter.

Best Practices for MIG Welding

For high-quality results, welders follow proven techniques and machine setups.

1. Set the Correct Voltage & Wire Speed

Voltage controls arc length.

Wire speed controls deposition rate.

Too much voltage → excess spatter

Too little voltage → unstable arc

2. Maintain Proper Stick-Out

Correct MIG stick-out is ⅜”–½”.

Too long reduces penetration; too short causes excessive heat.

3. Use the Right Travel Angle

- Push angle (10–15°) → flatter, cleaner weld

- Pull angle → deeper penetration

Most MIG applications use a push technique.

4. Correct Work Angle

- 90° for flat joints

- Adjust 5–15° to prevent undercut or overlap

5. Keep Your Welding Area Clean

Remove:

- Rust

- Paint

- Grease

- Moisture

You’ll get better penetration and fewer weld defects.

6. Optimize Shielding Gas Flow

Typical flow rate: 20–30 CFH.

Too low → porosity

Too high → turbulence and contamination

7. Choose the Right Joint Preparation

Common MIG joint types include:

- Butt joints

- Fillet joints

- Lap joints

- T-joints

- Edge joints

Correct beveling improves penetration on thicker materials.

8. Maintain Equipment

Clean your:

- Contact tips

- Wire drive rollers

- Liners

- Nozzle

This reduces feeding issues and improves arc stability.

Common Applications of MIG Welding

MIG welding is used in nearly every metalworking industry due to its speed and simplicity.

🏭 Industrial Fabrication

Structural steel, frames, platforms, catwalks, brackets, and custom steel components.

🔧 Automotive Repair

Body panels, exhaust systems, brackets, aluminum components, and trailer repair.

🚜 Heavy Equipment Welding

Buckets, blades, trailer frames, skid steer attachments, and wear plating.

🏗️ Construction

Handrails, beams, steel structures, gates, stairs, and on-site steel fabrication.

🛠 Manufacturing

High-volume production lines rely on MIG welding for its speed and consistency.

🚚 Aluminum Repair & Fabrication

Fuel tanks, boxes, decks, frames, and trailer components.

🧰 General Metal Repair

MIG welding is ideal for hobbyists and professionals repairing:

- Cracked steel

- Broken brackets

- Damaged frames

- Farm equipment

Why MIG Welding Is a Preferred Choice for Professionals

Professional welders and fabrication companies prefer MIG welding because it offers:

- High productivity

- Clean, consistent welds

- Minimal cleanup

- Adaptability for all skill levels

- Reliability across most metals and environments

From fabrication to repair work, MIG welding remains an essential tool for delivering strong, dependable welds with maximum efficiency.

Final Thoughts: Why MIG Welding Matters

Whether you’re repairing heavy equipment, fabricating new steel structures, or working with aluminum, MIG welding offers unmatched speed, versatility, and performance. With the right wire, gas, settings, and technique, MIG welding produces durable welds suitable for nearly every industry.